Why Choosing the Right Tapping Machine Matters in 2025

Choosing the right tapping machine can dramatically improve your workshop’s productivity, accuracy, and operational cost-effectiveness. In 2025, manufacturers face rising quality demands, tighter tolerances, and increased pressure to automate production. Whether you run a small workshop or a large-scale manufacturing line, selecting the correct tapping machine is essential for long-term success.

This guide explains everything you need to know before buying—types of tapping machines, when to choose electric vs servo vs pneumatic, price considerations for automatic tapping machines, and which model best suits your production needs.

The manufacturing industry today is evolving faster than ever. With CNC machining, robotic automation, EV components, precision engineering, and high-volume production becoming the norm, tapping accuracy and consistency are critical.

A high-quality tapping machine provides:

- Higher threading accuracy

- Consistent torque control

- Reduced tap breakage

- Faster cycle times

- Lower rejection rates

- Longer tool life

- Higher operator safety

Choosing the wrong machine, however, can result in frequent tap breakage, misaligned threads, reduced productivity, and higher scrap.

This guide helps you avoid costly mistakes and pick the most suitable machine for your workshop in 2025.

What Is a Tapping Machine? (Basics & Industrial Role)

A tapping machine is used to create internal threads (tapped holes) in materials like steel, aluminum, cast iron, plastic, or brass. Modern tapping machines offer features like torque control, variable speed, automatic depth control, and flexible or rigid tapping systems.

Industries using tapping machines include:

- Automobile & EV components

- Electrical fittings

- Aerospace parts

- Fabrication & metalworking

- Machinery manufacturing

- Electronics & consumer appliances

- Hydraulic & pneumatic equipment

Key Factors to Consider Before Choosing a Tapping Machine

Before selecting any tapping machine, evaluate these critical factors:

✔ Thread Size & Material Hardness

Hard materials (stainless steel, alloy steel) require servo or electric tapping machines with precise torque control.

✔ Production Volume

- Low volume → Arm tapping machine, pneumatic tapping machine

- Medium volume → Electric tapping machine

- High production → Automatic tapping machine

✔ Accuracy & Precision Requirements

High-precision parts benefit most from servo tapping machines or vertical tapping machines.

✔ Operator Skill Level

Automated or servo-driven models reduce human error.

✔ Budget & ROI

A slightly higher initial investment often results in long-term savings through:

- Lower tap breakage

- Reduced rejection

- Higher consistency

✔ Machine Durability & Maintenance

Check availability of:

- Spare parts

- After-sales support

- Local service

Reliable tapping machine manufacturers ensure quick maintenance support, reducing downtime.

Electric Tapping Machines

Electric tapping machines are versatile and widely used for general workshop needs.

How Electric Tapping Machines Work

They use an electric motor to control spindle rotation, offering adjustable speed and smoother tapping.

Advantages of Electric Tapping Machines

- Easy to operate

- Good speed control

- Lower power consumption

- Ideal for small to medium production

- Affordable pricing

Limitations

- Not suitable for heavy-duty threading

- Less precise compared to servo models

Best For

- General fabrication

- Machine shops

- Mild steel, aluminum, plastic parts

Servo Tapping Machines

In 2025, servo tapping machines are among the most in-demand due to precision and torque control.

Why Servo Tapping Machines Lead in 2025

Servo motors provide:

- Accurate torque

- Precise depth control

- Smooth reversal

- Low tap breakage

Key Advantages of Servo Tapping Machines

- Ideal for high-precision threading

- Best for hard materials

- Perfect for repeated production cycles

- Low rejection rates

Best For

- Automotive & EV components

- Aerospace parts

- High-accuracy production lines

If your priority is precision and consistent performance, a servo tapping machine is the best choice.

Pneumatic Tapping Machines

Pneumatic tapping machines operate using compressed air and are known for their speed.

Advantages of Pneumatic Tapping Machines

- High tapping speed

- Lightweight & flexible

- Safe overload protection

- Affordable initial cost

Best Use Cases

- Fast-paced production

- Medium threading work

- Large workshops using air compressors

Limitations

- Less accuracy than servo machines

- Depends on air pressure stability

Vertical Tapping Machines

A vertical tapping machine is perfect for operations requiring stability and high alignment accuracy.

Benefits

- Rigid structure

- Perfect for precision components

- Stable vertical tapping motion

- Extremely consistent hole alignment

Ideal For

- Mass production

- Precision machining

- Automotive suppliers

- Component manufacturers

Arm & Flexible Arm Tapping Machines

Arm tapping machines allow the operator to move freely around large or awkward workpieces.

Advantages:

- Great reach & flexibility

- Ideal for large plates or heavy parts

- Quick positioning

Flexible Arm Tapping Machine

A better, upgraded version of the arm tapping machine.

Advantages:

- Smooth multi-directional movement

- Higher operator comfort

- Easy threading of oversized or fixed workpieces

- Reduces operator fatigue

Best For

- Fabrication units

- Heavy castings

- Large metal plates

- Irregular workpieces

Flexible arm tapping machines are trending in 2025 due to rising demand for ergonomic and scalable tapping solutions.

Automatic Tapping Machines

Automatic tapping machines are designed for high-volume production with minimal human involvement.

Benefits of Automation

- Unmatched speed

- Consistent tapping depth

- Zero operator errors

- Multi-spindle capabilities

- Lowest rejection rate

Automatic Tapping Machine Price Factors

Prices vary based on:

- Machine type (single spindle, multi-spindle)

- Servo or electric configuration

- Automation level (PLC/CNC)

- Custom fixtures

- Thread size capacity

While the initial investment is higher, ROI quickly improves due to reduced labor costs and improved output.

Best For

- Large factories

- High-volume production

- Automotive & electrical industries

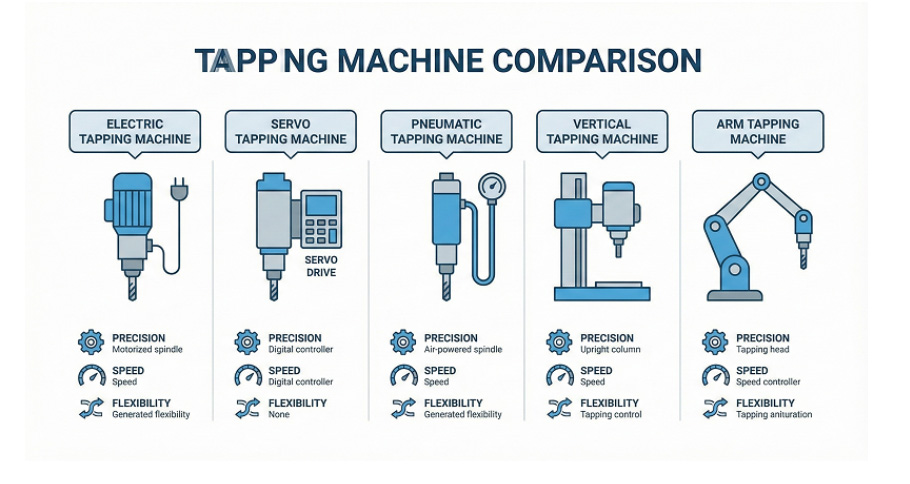

Comparison Chart: Electric vs Servo vs Pneumatic vs Arm vs Automatic

| Machine Type | Precision | Speed | Best For | Cost | Production Scale |

|---|---|---|---|---|---|

| Electric Tapping Machine | Medium | Medium | Small–Medium shops | Affordable | Medium |

| Servo Tapping Machine | Very High | Medium–High | Automotive, EV, Aerospace | Higher | Medium–High |

| Pneumatic Tapping Machine | Medium | Very High | Fast operations | Affordable | Medium |

| Vertical Tapping Machine | High | Medium | Precision machining | Moderate | Medium–High |

| Arm Tapping Machine | Medium | Medium | Large workpieces | Affordable | Low–Medium |

| Flexible Arm Tapping Machine | Medium–High | Medium | Heavy or awkward parts | Moderate | Medium |

| Automatic Tapping Machine | Very High | Very High | Mass production | High | High |

Choosing the Right Model for Your Workshop Size

For Small Workshops

- Electric tapping machine

- Pneumatic tapping machine

- Arm tapping machine

For Medium Manufacturing Units

- Servo tapping machine

- Vertical tapping machine

- Flexible arm tapping machine

For Large Production Facilities

- Automatic tapping machine

- Multi-spindle tapping system

Common Mistakes to Avoid When Buying a Tapping Machine

With a weight of 32–40 kg and a radius of 1100–1200 mm, the machines are easy to move yet stable enough for heavy-duty industrial tapping.

- Choosing too low a torque machine for hard materials

- Ignoring tap breakage & maintenance cost

- Selecting a low-quality tapping machine manufacturer

- Not planning for future production growth

- Ignoring after-sales service availability

Maintenance Tips for Higher Accuracy & Longer Machine Life

- Lubricate moving components regularly

- Inspect tap wear and replace timely

- Maintain stable electrical/air supply

- Keep machine clean from chips

- Train operators periodically

- Use high-quality taps suited to material

Conclusion: Making the Best Machine Choice for 2025 and Beyond

Choosing the right tapping machine in 2025 comes down to understanding your workshop’s needs—precision, speed, production volume, and budget. Whether you need a servo tapping machine for accuracy, a pneumatic model for speed, or an automatic tapping machine for mass production, selecting the right machine will significantly improve your output quality and reduce tap breakage.

Raveco Machines offers a complete range of tapping solutions engineered for durability, stability, and performance. If you want reliable machines that improve your threading efficiency:

👉 Explore the full tapping machine range:

https://www.ravecomachines.com👉 Speak with a technical expert:

https://www.ravecomachines.com/contact.html👉 Learn more about why workshops prefer Raveco:

https://www.ravecomachines.com/about.htmlYour perfect tapping machine for 2025 is just one click away.

FAQs

1. Which tapping machine is best for beginners?

Electric tapping machines are the easiest to use and maintain.

2. Is a servo tapping machine worth the cost?

Yes—if your work requires high precision, consistent torque, and minimal tap breakage.

3. What affects automatic tapping machine price?

Automation level, spindle configuration, thread size, and customization.

4. Which machine gives the least tap breakage?

Servo tapping machines and automatic tapping machines.

5. Can a flexible arm tapping machine replace a vertical tapping machine?

Not fully—vertical machines offer higher rigidity, while flexible arm machines offer mobility.